Truck repair is an essential part of maintaining the longevity and reliability of commercial and personal trucks. Whether you’re dealing with minor issues like oil changes or major engine repairs, understanding the basics of truck maintenance and repair can save you money and ensure safety on the road. In this comprehensive guide, we will explore the various aspects of truck repair, common issues truck owners face, and tips for maintaining your vehicle.

Understanding Truck Mechanics

Before diving into the specifics of truck repair, it is essential to understand the various systems and components that make up a truck. Trucks, like any vehicle, consist of numerous mechanical and electrical systems that work together to provide transportation for goods and passengers. A basic understanding of these systems can help truck owners identify potential issues and seek appropriate repairs.

Types of Trucks

There are different types of trucks designed for various purposes, and understanding the type of truck you have can influence the repair process. Trucks are generally classified into light, medium, and heavy-duty categories, with each having its unique set of repair needs.

- Light-Duty Trucks: These trucks, such as pickup trucks, are typically used for personal transportation or light commercial work. Common models include Ford F-150, Chevrolet Silverado, and Toyota Tacoma.

- Medium-Duty Trucks: These trucks, such as delivery trucks and utility vehicles, handle heavier loads and often require more specialized repair services.

- Heavy-Duty Trucks: Large commercial vehicles like semi-trucks and dump trucks fall into this category. They are built for long-distance hauling and heavy loads, making their repair needs more complex.

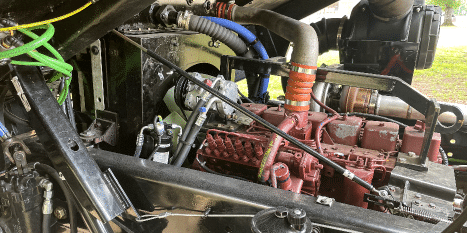

Major Truck Systems

- Engine: The heart of the truck, the engine provides power to the vehicle. Truck engines are generally larger and more powerful than car engines, often requiring specialized knowledge for repairs.

- Transmission: Responsible for shifting gears, the transmission is crucial for smooth acceleration and efficient power transfer. Both manual and automatic transmissions are common in trucks.

- Brakes: Truck brake systems are more robust than those in smaller vehicles, as they must handle greater weight and stress.

- Suspension: A truck’s suspension system supports the vehicle’s weight, absorbs shocks from the road, and maintains proper tire contact.

- Electrical System: The electrical system powers everything from lights and gauges to engine management systems.

Common Truck Problems and Repairs

Trucks, especially those used in commercial fleets, are subject to heavy wear and tear. Frequent long-distance driving, heavy loads, and harsh working conditions make trucks more susceptible to mechanical problems. Below are some of the most common truck problems and the typical repairs required to fix them.

Engine Issues

The engine is one of the most critical and complex components of a truck. Engine issues can range from minor fixes like spark plug replacements to more severe problems such as a blown head gasket.

- Oil Leaks: A common issue in trucks is oil leaks, which can occur due to worn-out seals or gaskets. Ignoring oil leaks can lead to engine overheating or even complete engine failure.

- Fuel Injector Problems: Fuel injectors can become clogged or damaged over time, leading to poor engine performance or reduced fuel efficiency. Cleaning or replacing the injectors is often necessary.

- Turbocharger Failures: Many diesel trucks rely on turbochargers for increased power and efficiency. Over time, turbochargers can wear out or become damaged, leading to a loss of power and poor fuel economy.

Transmission Problems

Truck transmissions, especially in heavy-duty vehicles, are designed to handle large amounts of torque. However, transmission failures can occur due to various reasons.

- Slipping Gears: When a truck’s transmission slips gears, it may feel as though the vehicle is changing gears without driver input. This can be caused by low transmission fluid, worn clutch components, or internal transmission damage.

- Transmission Fluid Leaks: A leak in the transmission fluid can lead to serious damage if not addressed promptly. The transmission fluid is vital for lubricating the gears and ensuring smooth operation.

Brake Repairs

The braking system in trucks is larger and more complex compared to that of smaller vehicles due to the heavier loads they carry. Common brake issues include:

- Worn Brake Pads: Brake pads in trucks wear out faster due to the increased stress they are subjected to. Replacing brake pads regularly is crucial for safe operation.

- Brake Fluid Leaks: Trucks use hydraulic systems for braking, and a leak in the brake fluid can lead to reduced braking power or complete brake failure.

Electrical System Failures

The electrical system in a truck controls everything from the ignition to the lights. Common electrical issues include:

- Dead Batteries: Truck batteries can fail due to age, excessive heat, or leaving electrical components on for too long. Replacing the battery is usually a straightforward repair.

- Faulty Alternator: The alternator charges the battery and powers the truck’s electrical systems. A faulty alternator can cause the battery to drain, leading to a truck that won’t start.

Routine Maintenance for Trucks

Routine maintenance is key to keeping a truck running efficiently and preventing major repairs down the line. Regular maintenance not only extends the life of the truck but also ensures the safety of the driver and other road users.

Importance of Regular Inspections

Frequent inspections allow you to catch potential issues before they become costly repairs. Professional mechanics can assess key systems such as the engine, transmission, and brakes during routine inspections. In commercial trucking, inspections are often mandated by regulations to ensure that the vehicle is safe for the road.

Oil Changes

Changing the oil in a truck is crucial for maintaining the health of the engine. Engine oil lubricates the moving parts of the engine, preventing wear and tear. In trucks, oil changes may be required more frequently due to the heavy use of the vehicle.

- Oil Filter Replacement: Along with the oil, the filter should also be replaced to ensure clean oil is circulating through the engine.

- Oil Types: Trucks, especially diesel ones, require specific types of oil. Consult your owner’s manual or mechanic to ensure the right type of oil is used.

Tire Maintenance

Tires are one of the most critical components of a truck, affecting both safety and fuel efficiency.

- Tire Rotation: Regularly rotating the tires helps to even out the wear, extending the lifespan of your tires.

- Tire Pressure Checks: Ensuring the tires are properly inflated helps with fuel efficiency and prevents premature tire wear.

- Alignment and Balancing: Misaligned tires or unbalanced wheels can cause uneven tire wear and reduce handling.

Truck Repair Tools and Equipment

Having the right tools is essential for truck repair, whether you are performing basic maintenance or more complex repairs. Below is a breakdown of some essential tools and advanced equipment used in truck repair.

Essential Tools for Truck Repair

- Socket Set: A high-quality socket set is indispensable for working on trucks, allowing you to tighten or loosen various nuts and bolts.

- Torque Wrench: Ensuring that bolts are tightened to the correct specification is crucial, especially for engine components.

- Hydraulic Jack and Jack Stands: Trucks are heavy, and using a reliable hydraulic jack and jack stands is essential for safely lifting the vehicle.

- Pry Bars and Hammers: For removing stuck components, pry bars and heavy-duty hammers are often needed.

Diagnostic Tools and Technology

Modern trucks are equipped with complex electronic systems that require specialized diagnostic tools to assess and repair.

- OBD-II Scanner: An On-Board Diagnostics (OBD-II) scanner is used to read trouble codes from the truck’s computer, allowing you to identify issues quickly.

- Multimeter: A multimeter is useful for diagnosing electrical problems by measuring voltage, resistance, and continuity in circuits.

- Brake Bleeder Kit: For trucks with hydraulic brakes, a brake bleeder kit is necessary to remove air from the brake lines after repairs.

DIY Truck Repairs vs Professional Services

When it comes to truck repair, deciding whether to handle it yourself or take the vehicle to a professional mechanic is an important consideration. Both approaches have their pros and cons, and the choice will depend on the complexity of the issue and your skill level.

Pros and Cons of DIY Repairs

Pros:

- Cost Savings: DIY repairs can save you money, especially for minor issues such as oil changes or replacing brake pads.

- Learning Experience: Working on your own truck can provide valuable hands-on experience and a better understanding of how your vehicle operates.

Cons:

- Time-Consuming: Some repairs can take a significant amount of time, especially if you lack experience.

- Risk of Further Damage: Without the right tools or knowledge, you could inadvertently cause more damage to your truck.

When to Consult a Professional Mechanic

For complex issues such as transmission failures or major engine problems, it’s often best to leave the repair work to a professional mechanic. Professional mechanics have access to specialized tools and parts, as well as the experience to diagnose and fix problems efficiently.

- Transmission Repairs: Transmission issues are intricate and may require specialized tools and knowledge.

- Engine Overhauls: Rebuilding or overhauling an engine is a major task that requires professional expertise.

- Electrical Problems: Diagnosing and fixing electrical issues can be complicated, and a professional can often pinpoint problems more quickly using advanced diagnostic equipment.

Preventive Measures for Long-Term Truck Health

Taking preventive measures is key to avoiding costly truck repairs and ensuring that your vehicle remains in good working condition for years to come. Below are some of the most effective ways to maintain your truck’s health.

Preventive Maintenance Plans

Many truck owners and fleet operators develop preventive maintenance plans to ensure that trucks receive regular inspections and upkeep. This can include:

- Scheduled Oil Changes: Regularly changing the oil and oil filter helps keep the engine running smoothly.

- Brake Inspections: Regular brake checks can prevent unexpected failures and ensure that the truck stops safely.

- Fluid Checks: Checking and topping off fluids such as transmission fluid, brake fluid, and coolant is essential for proper vehicle function.

Safe Driving Practices

In addition to maintenance, how a truck is driven plays a significant role in its longevity.

- Avoid Overloading: Overloading a truck can put unnecessary strain on the suspension, engine, and brakes, leading to premature wear and tear.

- Smooth Driving: Avoiding sudden acceleration, hard braking, and rough driving can help extend the life of the truck’s mechanical systems.

Cost of Truck Repairs

Truck repair costs can vary significantly depending on the type of truck and the nature of the repair. Below is a breakdown of common truck repair costs and tips for saving money.

Breakdown of Typical Repair Costs

- Oil Change: $100 to $300, depending on the type of oil and truck model.

- Brake Repairs: $300 to $700, depending on the extent of the damage and whether you are replacing pads, rotors, or calipers.

- Transmission Rebuild: $3,000 to $5,000, depending on the truck model and the extent of the repair.

- Engine Overhaul: $5,000 to $10,000 for major engine repairs or replacements.

Tips for Saving Money on Repairs

- Regular Maintenance: Preventive maintenance can help you avoid costly repairs by catching issues early.

- Shop Around: Get quotes from multiple mechanics to ensure you are getting a fair price.

- Use Aftermarket Parts: In some cases, aftermarket parts can be more affordable than OEM (original equipment manufacturer) parts without sacrificing quality.

Truck repair is a broad and complex field, but understanding the basics can go a long way in ensuring the safety and reliability of your vehicle. Whether you are performing routine maintenance, addressing common truck problems, or deciding when to consult a professional, staying informed will help you make the best decisions for your truck. Proper care, preventive maintenance, and smart repair strategies can keep your truck running smoothly for years to come.